CyberHandler Custom

Maximum potential savings with Free Cooling

Featuring a highly efficient indirect/direct evaporative Free Cooling design and state-of-the-art components the custom AHUs minimize the running costs and achieve lower pPUE values, depending on application and location.

Product Overview

Most important benefits

- Ready for roof and wall installation

- Easy access for maintenance

- Multiple cooling systems integrated: Indirect and Direct Free Cooling, adiabatic evaporative cooling, mechanical cooling (as top-up or redundancy)

Most important features

- Custom sizes

- Multiple airflow configurations possible

Most important technical data

- Cooling capacity (kW): 50 – 700

- Flexible adaption to every project

- Ready for roof and wall installation

- The best casing leak classification according to the standard EN1886 (L1/L1)

- Easy access for maintenance

- Designed to fit standard transportation

- Flexible modular installation

- Multiple cooling systems integrated: Indirect and Direct Free Cooling, adiabatic evaporative cooling, mechanical cooling (as top-up or redundancy)

- Custom sizes

- Multiple airflow configurations possible

- Optimized design for minimum pressure losses

- Several filter classes available: G4, M5, F7 and F9

| Cooling capacity total (kW) | 50 – 700 |

| Installation | Wall, Roof |

| Airflow volume (m³/h) | 13,000 – 175,000 |

| Sizes | Custom sizes |

| Refrigerants | R513a optional (GWP: 573) |

All details about CyberHandler Custom

The complete solution

CyberHandler Custom is more than just a product. We offer a full range of services and features related to evaporative coolers, providing you a turnkey solution for data center cooling.

- For small to large data centers

- Indirect Free Cooling

- Adiabatic evaporative cooling

- IT sector

- Flexible adaptation to every project

Technology and infrastructure

- Indirect Free Cooling: No contamination from outside air

- Industry-leading efficiency levels with lower pPUE values, depending on application and location

- Year-round operation with adiabatic cooling via evaporation

- Outdoor installation – Saves space in the data center

Operating modes

The special construction with its extremely efficient combination of Free Cooling and adiabatic evaporative cooling reduces energy costs. The system has been optimized to such an extent that in most regions, 100 % mechanical cooling is no longer necessary.

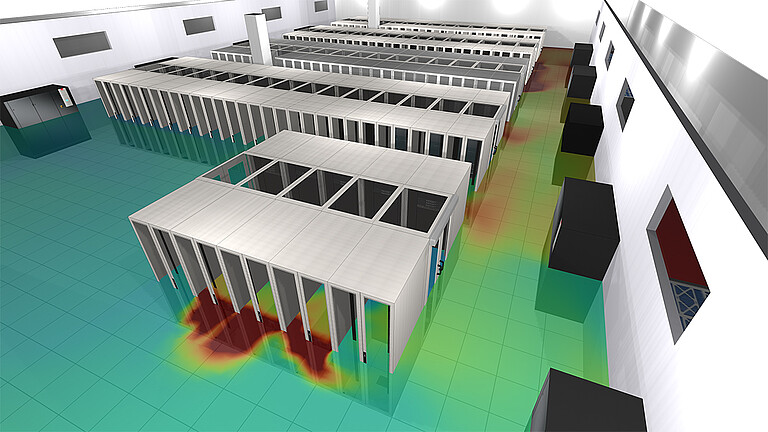

CFD simulation

Comprehensive control over all relevant factors is vital to achieve optimal performance and efficiency in a data center. STULZ contributes to this goal by providing the CFD (Computational Fluid Dynamics) service for data centers, using its unique fluid dynamics expertise at the product level to make the CFD simulation more accurate at the application level.

Installation configurations

Our high-performance air handling units are positioned directly on or next to the building. All the necessary cooling components are integrated in the units' housing, saving floor space in the data center and facilitating maintenance, as the service engineers no longer need to enter the data center.

Service

- Simplified installation:

Problem-free routing of power cables, water pipes and other piping outside the data center - Optimized maintenance conditions

- Service engineers do not have to enter server rooms

- Fast, low-cost maintenance - Low total cost of ownership (TCO)

- Simplified capital expenditure (CAPEX), operating expenditure (OPEX), and repair and infrastructure costs

- Reduced electrical infrastructure enables CAPEX savings of 6-8 %

Climate. Customized.

From standard units to fully customized solutions

The ability to offer such a wide range to customers is the embodiment of our philosophy, "Climate. Customized.". Size, design, air conduction, system or control: STULZ’s CyberHandler Custom can be precisely adapted to your individual requirements. In addition, a variety of options and equipment are available to achieve the optimum result.

Test Center

In our Test Center, located near Madrid in Spain, we can perform a variety of tests on the units in a state-of-the-art test chamber. This enables our clients to witness custom Air Handling Units operating under simulated extreme conditions, providing critical information such as performance data, energy consumption and water consumption.

Test parameters

- Function tests for simulating the safety features

- Physical dimensions of the units

- IT load up to 700 kW

- Airflows up to 175,000 m3/h

- Outdoor ambient conditions:

- Temperature range from +10 to +50 °C

Learn more about our Test Center.